Food

packaging

Confectionery

packaging

WORLD WATER DAY 2024

25/03/2024

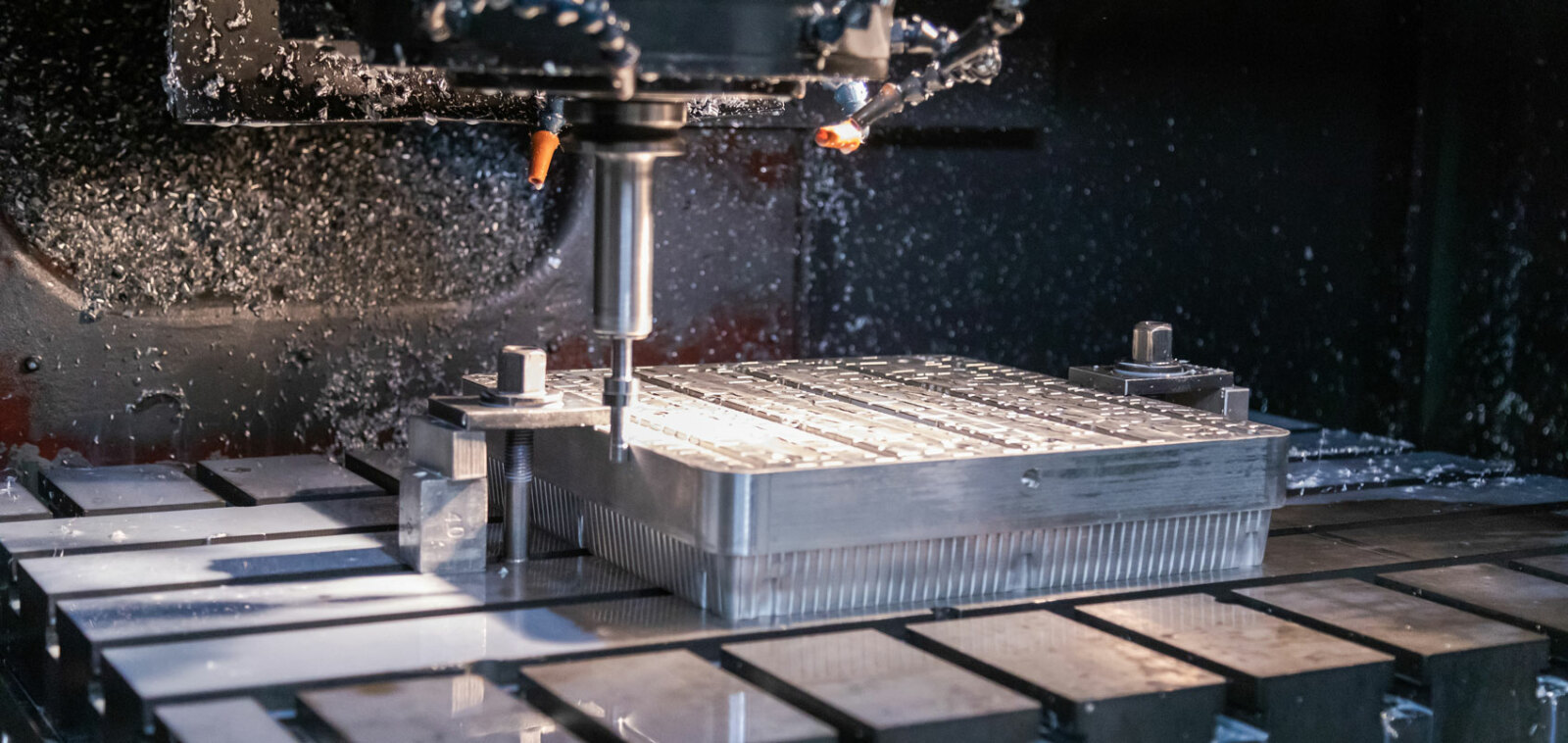

Mindful of our impact on the environment, ANL Packaging is actively engaged in the development of responsible industrial resources. In this #Worldwaterday, we would like to highlight the commitment of our sites to the preservation of this resource. This is because the polymer transformation process has the advantage of using only a limited amount of water. This water is mainly used to cool our tools and is retained in a closed loop that is reused continuously. In addition, ANL Packaging is participating in Operation Clean Sweep®, a programme designed to limit the loss of granules and flakes into the environment by means of containment measures and targeted, regular cleaning of high-risk areas. Find all our CSR commitments in our annual report available here. #WorldWaterDay #CSR #OceanCleanSweep #Environnement

CFIA Rennes 2024

12/02/2024

Somater & ANL Packaging will be exhibiting at #CFIARennes24, the unmissable event for tommorow’s #food and #foodpackaging players! Come and meet us and discover the breadth of our #technological platforms and our #knowhow! We look forward to seeing you there! 📅March 12-13-14 📢Hall 10- Booth G15

Silver Ecovadis

15/01/2024

ANL Packaging awarded silver medal one more time by Ecovadis!With our silver medal, ANL Packaging is in the top 25% companies assessed by Ecovadis.At a time when sustainability has become essential for our future, this result reflects and rewards our commitment to making our environmental, social and ethical practices ever more virtuous.We are grateful to our customers, partners and engaged teams for having enabled this recognition.