For every problem there's a solution

Packaging doesn't just protect your product. It also has to catch the eye of the consumer without losing functionality.

To ensure this functionality, there's some things to consider.

- Home

- Competencies

- designing packaging

Click on the icons below for more information.

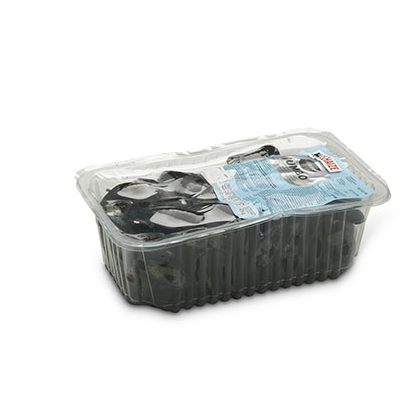

TransparENCY

Transparency is becoming increasingly important in our packaging, and we are seeing rising demand in the foodstuffs world in particular. Transparent packaging increases the perception of freshness, and purchasers can see the quality and the contents of what they are buying straight away. The latter is of increasing importance now that millennials are to a greater extent doing their own shopping. This group is characterised by a strong drive towards personalisation, which means that they identify less and less with brands. They are looking for new taste sensations, eat small portions more times a day and are willing to pay more for quality. At the shelf, this results in more sales of small portions, more sales "on sight" and healthier choices. The way your product is presented is therefore of prime importance.

ANL Packaging provides you with the highest level of transparency in PP as well as PET. PP is preferable because of its optimum industrial processability. We have therefore developed a PP that gives an exceptional level of transparency without affecting these good characteristics.

In combination with the extremely high-quality finish of the mould, this results in crystal clear packaging which presents the contents to perfection.

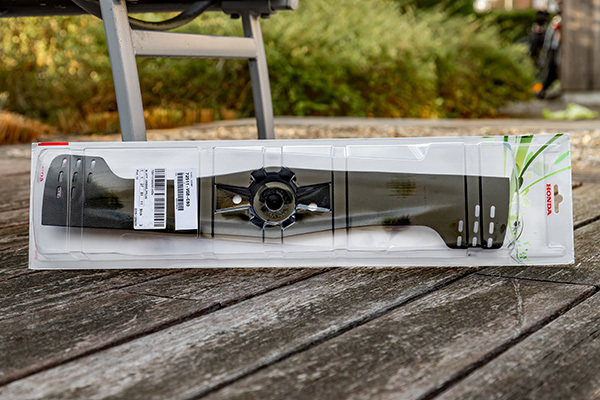

Reclosability

Reclosable packaging is nothing new. Reclosability is essential for certain categories of packaging. Examples of these are shampoo, engine oil, fabric softener, glass jars, etc., and reclosability is being extended more and more into other categories where the effects of oxygen are detrimental for the product. One of the biggest problems here is the drying-out of foodstuffs. Fresh food such as cheese, cold meats, prepared salads, etc. can be badly affected by oxygen. Once opened, they dry out unless they are repacked.

Having the packaging reclosable has a double benefit. Food stays fresh for longer and in its own packaging, which means that the brand is visible during the entire life of the product. Reclosability is real added value in the packaging of fresh foodstuffs.

There are a large number of innovations in the field of flat reclosable packaging. A clear distinction we can make here is between reclosability on the one hand by means of an adhesive layer such as is used on resealing films, and on the other hand by using a lid. Lids can be separate or attached, or even integrated with the container

Reclosability & portion packaging: one time to the shop to consume multiple times, easier to measure and cheaper to buy because of economies of scale.

Shelf life

Packaging is an essential element in the struggle against food waste. Extending the shelf life of fresh products is highly desirable. Modified atmosphere packaging is the solution for food producers who want to increase the shelf life of their products significantly without using preservatives that could have a noticeable effect. In the light of the trend for clean labelling, producers are making less and less use of chemical preservatives and are seeking alternatives such as MAP.

In MAP the atmosphere in the packaging is replaced by a mixture of gases. This mixture depends on the type of foodstuff that is being packaged.

There are two elements that degrade the freshness of food. On the one hand, there is oxygen and on the other hand, there are bacteria. Each of these affects food in its own way. By replacing the oxygen present in the packaging it can no longer have a negative effect on the food. The composition of the mixture of gases can be adjusted so that it contains antibacterial constituents. This will inhibit the damaging elements appreciably and the shelf life can be increased considerably.

The success of this packaging is due partly to the increased shelf life, and for retailers, there are also logistical benefits and optimum product presentation. Food can be presented in high-quality transparent packaging, which optimally emphasises the freshness of the product.

Requirements for optimal shelf life:

Wall thickness is very important with gas-filled packaging. Walls that are too thick result in excessive use of material and therefore uneconomic and environmentally-unfriendly packaging. Walls that are too thin are not functional because the gas can escape through them and have an adverse effect on the atmosphere. This is an important consideration with thermoform seal trays because the film is stretched and the wall thickness is determined by the thickness of the film as well as the depth and the shape of the tray. We guarantee the optimum barrier strength of fully-customised packaging designs without the excessive use of material.

Permeability is determined by factors such as the basic material used for the packaging, the composition of the gas, the temperature at which the product is stored and the total surface area. The integrity of the sealing edge is an essential element in this. The packaging must be fully airtight in order to provide optimum atmospheric conditions. Our packaging has ultra-flat edges to which sealing seams can be attached in separate pieces. PET or PP packaging to which sealing film can be attached without any problem, minimising the risk of interrupting production.

Our plastic seal trays :

- Are resistant to surface damage

- Have reliable sealing characteristics

- Are anti-fog treated

- Have oxygen and carbon dioxide permeability

- Have a certain water permeability

- Longer shelf life, less food waste

AutomatION

We develop our products so that their use in your production is optimal

Destacking

VERTICAL STACKING

- sliding mechanism with sliding blades

- With moving tabs

HORIZONTAL STACKING

- Sliding mechanism with sliding blades

- With moving tabs

- With suction cups

Requirements for the packaging

Edge shape adapted to suit your method of destacking

Filling

- With measuring unit

- With robot

- Manual

Requirements for the packaging

Ergonomic shape or shape according to your requirements

SEALING

INLINE OR MANUAL

- Shape of the packaging

- Flatness of the edge

- Thickness of the edge

Requirements for the packaging

Size of the sealing edge

PROCESSING

- Bain-marie

- Pasteurisation

- Sterilisation

Requirements for the packaging

- Material according to the temperature

- Barrier film

- Shape of the packaging

- Material distribution

LIDDING

- Manual

- Automatic

Requirements for the packaging

- Clearance between container and lid

- Shape retention of the stack

- Conditioning (remaining in the container)

- Stacking together

DECORATING

- On the side

- On the top

- On the bottom

- Manual

- Automatic

Requirements for the packaging

- Material distribution

- Maintaining counter-pressure

- Flatness

SENDING

CARDBOARD

- Decorative strip

- Box with 1 open side

PLASTIC

- Shrink film

- Decorative strip

- Sleeve

Requirements for the packaging

- Material distribution

- Maintaining counter-pressure

- Flatness

- Stacking/staggered

- Size of the packaging depending on the outer packaging (box/crate)

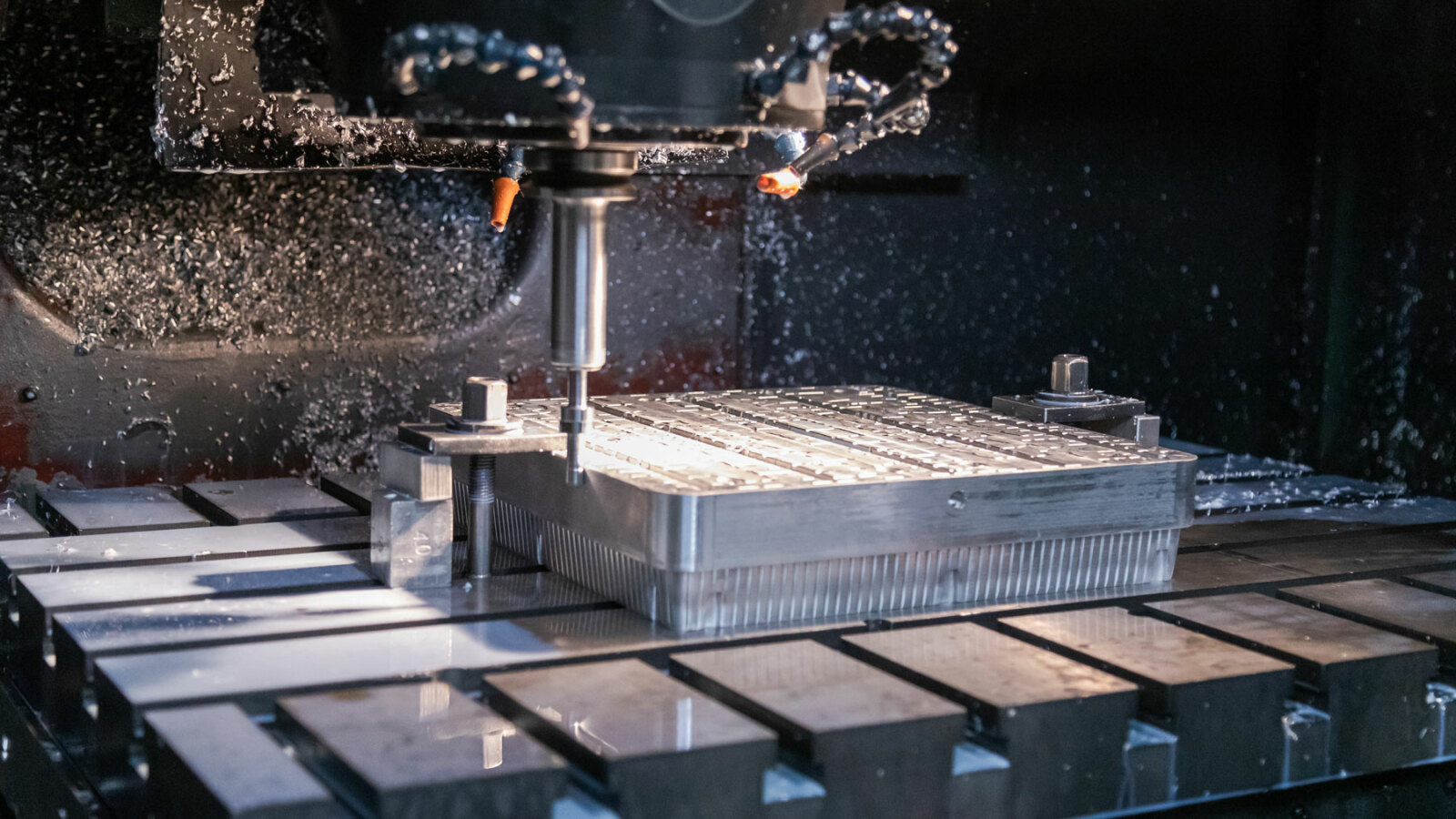

Design

A product can be distinguished from other products by its packaging. We support our clients and take care of their distinctive characteristics. Everything is done in accordance with a client’s brand image and their positioning in the market.

The packaging is intended to protect products. Good packaging is also user-friendly. When developing our products we focus on user-friendliness for the consumer:

- Visible opening

- Clarity about how the product has to be opened (e.g. using arrows or tabs)

- Avoiding people having to use excessive force or having to be too careful

Vertical presentation, horizontal presentation, flat walls, combined packaging, etc. The shapes of our packaging are harmonised with market trends. Our mission is to come up with packaging that is fully in line with the needs of the moment, which of course we do together with our clients.

We have a fully-integrated production process which we use to give shape to your packaging. We have everything in-house that is needed to develop your packaging from idea to delivery.

Every day we take up the challenge of creating state-of-the-art packaging. It is very important for us to develop the ultimate packaging that meets all possible requirements. This is an intensive process in which a great deal of knowledge is integrated with the actual design. We don’t do this behind closed doors, we do it together with you in a process of collaborative creation. Because it’s not just a plastic container: it’s your packaging.

Environment

For several years ANL Packaging has succeeded in various ways to make its products more sustainable. We have critically examined and subsequently optimised the existing processes in our three locations. We also have various initiatives in hand for continuing to do so in the future. We want to evolve sustainable policies in ecological as well as social fields.

Because product packaging meets many requirements, we cannot just leave these out of the production chain. As a large producer of packaging, ANL Plastics has taken up various initiatives for helping to make products that are more environmentally friendly:

- Developing products using as few raw materials as possible, without affecting our high standards where quality and performance are concerned.

- Developing lighter packaging. The average weight of our packaging has fallen by 20% in the last ten years.

- Developing concepts that help reduce waste mountain.

- Developing stackable, protective packaging that has less volume, takes up less storage space and has a large logistical benefit.

- Developing lighter materials that are a better alternative to other materials.

- Producing sustainable packaging: We use our SSP to process our PET recyclate so that we can reuse it without affecting the quality of the basic material. This machine enables us to recycle post-consumer waste into food-grade PET granulate that is fully EFSA certified.

Because product packaging meets many requirements, we cannot just leave these out of the production chain. As a large producer of packaging, ANL Plastics has taken up various initiatives for helping to make products that are more environmentally friendly:

- Developing products using as few raw materials as possible, without affecting our high standards where quality and performance are concerned.

- Developing lighter packaging. The average weight of our packaging has fallen by 20% in the last ten years.

- Developing concepts that help reduce waste mountain.

- Developing stackable, protective packaging that has less volume, takes up less storage space and has a large logistical benefit.

- Developing lighter materials that are a better alternative to other materials.

- Producing sustainable packaging: We use our SSP to process our PET recyclate so that we can reuse it without affecting the quality of the basic material. This machine enables us to recycle post-consumer waste into food-grade PET granulate that is fully EFSA certified.

Want to add value to your products?

ANL Packaging offers over 50 years of thermoforming craftsmanship and creativity.

In addition to high-quality standard references, the largest part of the ANL Packaging product range consists of bespoke references.

This enables us to enhance the individuality of the customers’ products.